Time:2022/09/30Views:158

About:

Knife gate valve is also known as knife gate valve, knife gate valve, slurry valve, mud valve, its opening and closing parts are RAMS, the direction of motion of the RAMS is perpendicular to the direction of the fluid, by cutting fiber material knife-shaped RAMS to cut off the medium, The gate has two sealing faces, the most commonly used mode of the gate valve two sealing faces form a wedge, the wedge Angle varies with the valve parameters, usually 5°, the wedge knife gate valve can be made into a whole, called rigid gate; It can also be made to produce a micro deformation of the ram, in order to improve its processability, make up for the sealing surface Angle in the processing of the deviation, this ram is called elastic ram. The valve body does not actually have a chamber, the gate is raised and lowered in the side guide groove, and is pressed against the seat by the bottom lug. If high dielectric sealing is required, the O-seal seat can be used to achieve a two-way seal. Knife gate valve has a small installation space, low working pressure, not easy to accumulate debris, low price.

When the knife gate valve is closed, the sealing surface can only be sealed by the medium pressure, that is, the medium pressure will press the sealing surface of the gate plate to the seat on the other side to ensure the sealing surface, which is self-sealing, most of the gate valve is forced to seal, that is, when the valve is closed, it must rely on external force to force the gate plate to the seat to ensure the sealing surface. This type of valve should generally be installed vertically in the pipeline.

Knife gate valve drive mode:

Manual, sprocket, electric, pneumatic, hydraulic, bevel gear, electronic hydraulic and gas hydraulic drive.

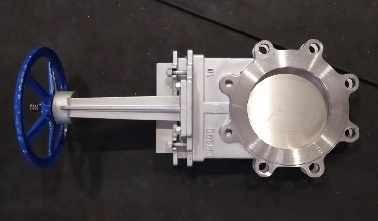

Knife gate valve appearance:

Open rod, dark rod two kinds. Knife gate valve material: cast iron, cast steel, carbon steel, stainless steel, fluorine lined, etc.

Knife gate valve seal:

Hard seal, soft seal, single-side seal, double-side seal and other materials seal.

Ultra-thin knife gate valve with its small size, small flow resistance, light weight, easy to install, easy to disassemble and other advantages completely solve the ordinary gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve and other valves of large flow resistance, large weight, difficult installation, occupy a large area and other difficult problems. After the advent of knife gate valves, a large number of general cut-off valves and regulating valves have been replaced by them. The world's largest knife gate valve usage is the United States and Japan.

The scope of use of knife gate valve is:

1. Mining, coal washing, iron and steel industry - used for coal washing pipeline, filter slurry pipeline, etc., ash discharge pipeline;

2. Purification device - used for wastewater, mud, dirt and clarified water with suspended matter;

3. Paper industry - used for any concentration of pulp, material and water mixture;

4. Power plant ash removal - used for ash slurry.